Industrial Fibre Optic Communications

Fibre optics (optical fibres) are long, thin strands of very pure glass about the diameter of a human hair. They carry much more information than conventional copper wire and one of the advantages of fibre cable is that it is completely insensitive to electromagnetic interference (EMI).

It is therefore ideal for installations in harsh industrial environments. It provides reliable transmission and high data transfer capacity over long distances. For example, almost all telephone long-distance lines (cross country) are fibre optic cables.

Advantages with Fibre Optic Cables vs. copper wire:

Fibre cables

There are a lot of different fibre optic cable types available on the market to meet different installation requirements. Internal grade cable is constructed to be flexible and lightweight and it may be coated to meet fire protection codes. External grade cable is constructed to withstand immersion in water, exposure to ultraviolet rays and attack by rodents and birds.

Fibre optic cable is constructed in several layers. The actual glass fibre consists of a central glass core that is surrounded by a layer called cladding of a different refractive index. This causes the light to travel in a controlled path along the entire length of the glass core. The glass fibre can be placed in a “tight” or “loose” buffer tube array, which is a protective covering that protects the fibre from sustaining damage. It also prevents light from escaping the assembly, and is often colour-coded for identification purposes. This allows for the necessary management of fibres due to the normally high counts contained within a cable. Tight-buffered cable is generally used in horizontal interior installations. The loose buffer tube array allows the glass fibre to “float” with considerable movement. As the fibre cable is installed (in conduit, directly buried, or placed on a pole) the glass fibres are not subjected to the forces of the pulling tension and therefore sustain minimal damage or distortion from stretching.

Material

The material used for the core and cladding differs on different types of fibre. The most common material used is glass. The glass used is extremely pure, silicon dioxide (silica). Other types of cable are PCS (Plastic Clad Silica) with a core of glass and an outer cladding of plastic, or a plastic fibre cable with both the core and outer cladding of plastic. Glass cable gives the best performance, but is more complicated to terminate. Plastic fibre on the other hand is easier to terminate, but offers very short transmission distances.

Type of Fibre Optic Cable

There are three types of fibre optic cables:

Multimode

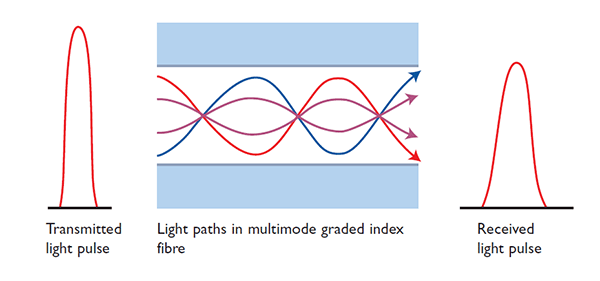

A multimode cable has a relatively large diameter core (50 to 400 microns where 62.5 is the most common one) and a total diameter of 125 microns. Multimode cables are available in two categories; these are graded index and step index. In a step index fibre, as modes reflect through the cable, some have to travel further than others and in doing so the light pulse will spread. This is one disadvantage, which means the fibre has a lower bandwidth. The solution to this problem is graded index. In these cables the refractive index reduces gradually from the core’s centre towards the cladding. This means that a light beam traveling mainly in the centre of the cable. This means higher bandwidth and lower attenuation.

Singlemode

A singlemode cable has a small core (3 to 10 microns where 9 microns is the most common) that forces the light to follow a more linear single path down the cable, as opposed to the multipath reflections of multimode cables.

The singlemode cable has the highest bandwidths and distance ratings.

Attenuation / Wavelength

The attenuation in the cable depends on several parameters where wavelength, material and pureness are three important factors.

The attenuation is measured in dB/km and can vary from 0.4 (singlemode) up to 1000 dB/km (plastic).

The common wavelength is 650 nm on plastic, 820 – 1300 nm on multimode and 1300 – 1550 nm on singlemode cables.

Transceivers and Connectors

Fibre optic transceivers usually include both a transmitter and a receiver in the same component. These are arranged in parallel so that they can operate independently of each other. Both the receiver and the transmitter have their own circuitry so that they can handle transmissions in both directions.

Termination / Patch Panels

There are many different ways to terminate fibre cables. One simple procedure called “crimp and cleave” is to crimp the connector on to the fibre (this requires special pliers) and then cleave the fibre very carefully. Another more reliable procedure is to use an epoxy to bond the fibre into the connector; connectors are available with the adhesive already in the connector. The connector is then heated with the help of a special oven for around 1 minute; the fibre is inserted in the connector and is then allowed to cool. These two terminating methods both require equipment to prepare the fibre before mounting the connector and to polish the fibre after the cable is terminated. In systems where connection points are frequently changed the epoxy bonded connectors may be beneficial, as this gives a more durable termination. In larger systems a patch panel is often used at the centre of the installation. From the patch panel a short patch cable is used to connect to the fibre optic equipment. The patch cable can for example be terminated with an ST-connector at one end and an LC-connector at the other to fit in both the patch panel and the fibre optic device.

ST-Connector

Simplex connector used for single- or multimode cables.

LC-Connector

Duplex connector used for single- or multimode cables on the ODW-series.

LC-Transceiver

The transceiver used in the ODW-series is an SFP transceiver (Small Form - Factor Pluggable), which offers a flexible configuration.

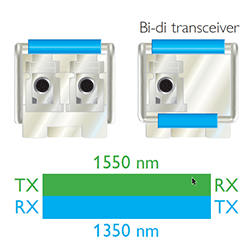

It’s also available as a Bi-directional transceiver (full duplex on a single fibre).

SC – Connector

Simplex and duplex connectors used for single- or multimode cables.

BiDi Transceivers

Bi-directional transceivers offer the possibility of full duplex communication on a single fibre using different wavelength.

The BiDi transceiver uses two different wavelengths of laser or LED light. One in each direction to transmit and receive data simultaneously. The different wavelengths of light are in effect isolated from each other so it cannot cause interference or errors in the data flowing in each direction. The use of BiDi transceivers can save costly replacements or increase the number of data services over an existing fibre cable.

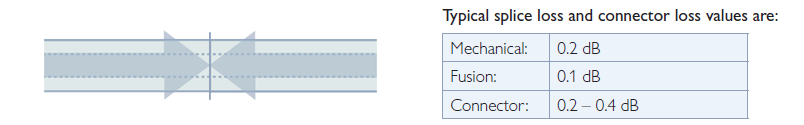

Light loss in splices and connectors

Connector and splice loss is caused by a number of factors. Loss is minimised when the two fibre cores are identical and perfectly aligned, the connectors or splices are properly finished and no dirt is present.

Only the light that is coupled into the receiving fibre’s core will propagate, all the rest of the light effectively becomes the connector or splice loss.

The end finish of the fibre must be properly polished to minimise loss. A rough surface will scatter light and dirt can scatter and absorb light. Since the optical fibre is so small, typical airborne dirt can be a major source of loss.

The pictures show a multimode cable 200x magnification where the left picture is clean, the one in the middle has dust particles and the one on the right is contaminated with liquid.

Whenever connectors are not terminated, they should be covered to protect the end of the ferrule from dirt. One should never touch the end of the ferrule, since the oils on one’s skin causes the fibre to attract dirt. Before connection and testing, it is advisable to clean connectors with lint free wipes moistened with isopropyl alcohol.

Different Configurations

Fibre Optic Solutions

A fibre solution is usually applied in situations where normal copper cable is inadequate. It may be that the network needs to be extended beyond the limit of normal copper cable, or the network to be lead into heavy industrial environments not suitable for standard Ethernet or coaxial cable.

Network topologies

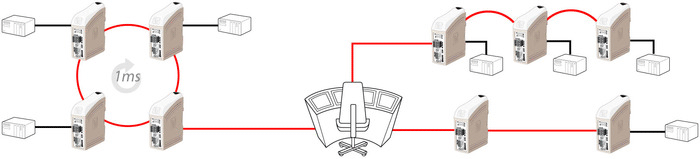

Our extensive fiber range allows you to build any type of network topology. Ring Networks with standard STP / RSTP, or our own super-fast FRNT redundancy protocol, star networks, multidrop networks or point-to-point connections. Our fiber switches are fully managed with routing functionality that allows simple solutions to complex networking needs.

Serial networks

For serial networks, our ODW-series provides a easy to install, robust and reliable solution over fiber optic cable. The ODW-series supports the most common serial protocols, RS-232, RS-422, RS-485 and Profibus. Models are available for ring and multidrop network and point-to-point networks. In ring networks, we can offer less than 1 ms reconfiguration times in networks with up to 200 devices.

Connect serial and IP-based networks

Our fiber product range is fully compatible and makes it possible to combine serial and Ethernet networks. For applications requiring high availability and resilience, individual ring networks can be combined which allow hundreds of devices to be connected in a ring with re-configuration-times less than 1 ms.

Credits: Westermo