The Throughput Connection

This is the latest edition - your gateway to cutting-edge industrial networking.

Words From the Tech Desk

We face forward with pronounced optimism

Named for Janus, the two-faced god of gates and doorways, January compels us to look back and ahead. As we close the gate on 2025, we do so with gratitude for its lessons - each setback a catalyst for refinement, each success a foundation to build upon. We carry that clarity into 2026.

Now, we face forward with pronounced optimism. The horizon is active with expansion. Foundational industries driving global infrastructure and modernization are entering a phase of robust investment and innovation. This isn't vague hope; it's a tangible shift, creating a landscape rich with complex challenges and even richer with opportunity. For partners like you, it signifies new projects, evolving demands, and a clear path for growth.

At Throughput, we are strategically positioned and energized to navigate this promising terrain alongside you. Our commitment is to provide the seamless, reliable solutions that turn this potential into mutual prosperity and enduring success.

Let’s embrace this pivotal year together. From all of us, we wish you a 2026 of significant breakthroughs and collective achievement. The doorway is open. Let’s step through.

Onward,

Anton van der Westhuizen

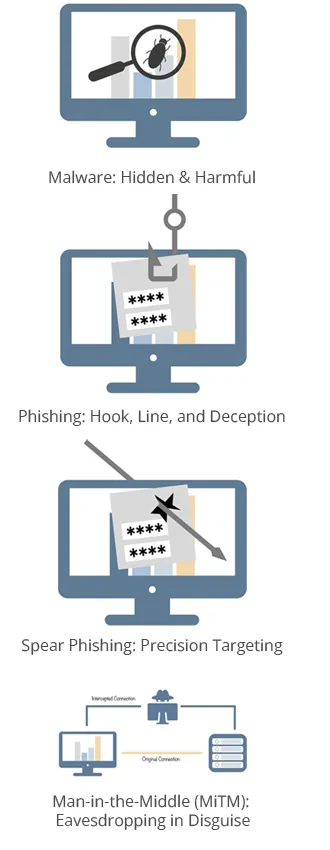

Cybersecurity in Industrial Networks: Beyond Passwords

In Operational Technology (OT) environments - think utilities, transportation, and energy - cybersecurity demands far more than changing default passwords. It requires proactive policies, vigilance, and a layered approach to protect mission-critical systems from disruption.

Here are common cyberattacks targeting OT networks and practical ways to spot them early.

Malware: Hidden Threats

Malware infiltrates via attachments or drives, stealing data or locking systems. Types include spyware (monitors activity) and ransomware (encrypts files for payment).

Spot it: Suspicious file types (.bat or disguised PDFs). Defend: Scan attachments; isolate OT networks. If unsure, don't open - alert IT.

Phishing: Impersonation Scams

Cybersecurity in Industrial Networks

Attackers pose as trusted sources with convincing emails containing malicious links.

Red flags: Urgent requests, odd sender addresses, generic greetings. Defend: Verify sources; use filters. Never share credentials without confirmation.

Spear Phishing: Targeted Deception

Personalised attacks mimic colleagues or executives, often with time pressure for sensitive data.

Example: Slight domain tweaks (e.g., "rn" mimicking "m") or fake senior requests. Defend: Double-check addresses; report anomalies. Apply least-privilege access.

Man-in-the-Middle (MitM): Interception

Attackers eavesdrop or alter data between devices.

Defend: Enforce VPNs/HTTPS; update firmware. Segment networks to limit exposure.

DDoS: Traffic Overload

Floods systems with junk data, causing outages.

Prevent: Firewalls; hide interfaces; monitor anomalies. Disable unused services.

Insider Threats: Internal Risks

Careless or malicious insiders enable damage.

Mitigate: Role-based access; audit logs; encourage reporting. Balance restrictions with trust.

Cybersecurity is teamwork: Train regularly, enforce policies, monitor proactively. Threats evolve - defences must too. In industrial networks, vigilance ensures resilience and uninterrupted operations.

Availability is another critical consideration. Denial-of-service attacks do not require system access at all - simply overwhelming a network can halt operations. Reducing exposure, disabling unused services, and monitoring traffic patterns are essential defensive measures.

Finally, the most underestimated risk is the human one. Most incidents are not malicious, but the result of error, misunderstanding, or misconfiguration. Overly restrictive controls encourage unsafe workarounds, while permissive systems invite abuse.

Cybersecurity in industrial networks is not a checklist exercise. It is an ongoing discipline that combines people, policy, and resilient architecture. When designed with visibility, segmentation, and longevity in mind, security becomes a natural property of the system - not an afterthought.

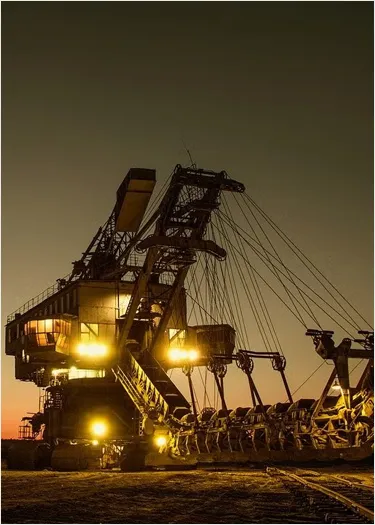

The Rise of Converged Networks in SA

The Rise of Converged Networks in SA

South Africa's mining industry is embracing digital transformation through the modernisation of its communications infrastructure. A major trend is the shift from isolated systems to unified, IP-based networks. This convergence integrates critical data - from telemetry and tracking to video and autonomous systems - onto a single, secure backbone.

Deployment of industrial-grade, multi-protocol solutions provides the deterministic performance and rugged reliability essential underground. These systems seamlessly bridge operations between subsurface and surface, connecting to remote control centres. The result is a holistic operational view that enables predictive maintenance, real-time decision-making, and enhanced safety.

By building this intelligent digital foundation, mines are unlocking new levels of productivity, safety, and long-term sustainability, transforming how resources and data are extracted.

FlexDSL: Extending Connectivity Where Fibre Can't Reach

FlexDSL provides robust telecommunications solutions that bridge modern IP networks with critical legacy infrastructure. Their expertise enables reliable, long-distance data transmission over existing copper cables - perfect for extending SCADA and control networks to remote sites without costly new fibre runs. The Orion SHDSL and MiniFlex platforms deliver the symmetrical, deterministic connectivity vital for operational technology.

Crucially, FlexDSL creates seamless migration paths. Their IP multiplexers consolidate legacy serial, TDM, and Ethernet interfaces into unified IP streams. This allows for phased network modernisation without operational disruption. By maximising existing copper while enabling controlled migration, FlexDSL is a strategic partner for utilities, transport, and industrial sectors building resilient, future-proof networks.

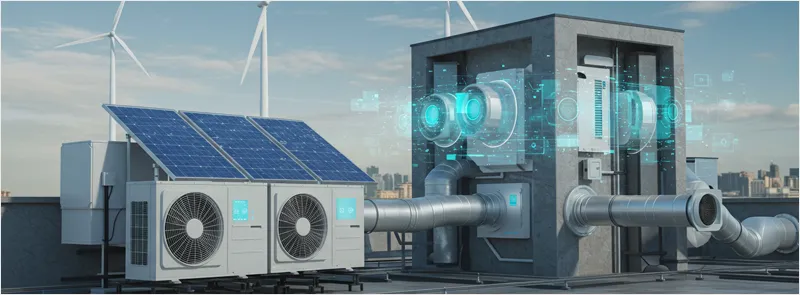

Unlock Smarter Buildings with Unified HVAC Control

How a single gateway bridges building automation and industrial networks to cut energy waste and boost operational efficiency.

In today's industrial and commercial facilities, HVAC systems often operate in silos - using BACnet, Metasys, or Modbus protocols that can't “talk” to the plant's PLCs or control systems. This disconnect leads to inefficiencies, reactive maintenance, and hidden energy waste.

Enter the ProSoft PS-QS-2x10-F QuickServer - a compact yet powerful communication gateway that breaks down these barriers. By translating between building automation protocols (like BACnet/IP, Metasys N2) and industrial networks (such as EtherNet/IP or Modbus TCP), it creates a unified data stream that flows seamlessly into central control platforms.

With the QuickServer, operators gain centralized visibility across chillers, rooftop units, and air handlers - regardless of brand or age. The gateway aggregates up to 1,000 data points, enabling real-time monitoring, remote access, and integration with cloud-based analytics for deeper insights.

The result? Proactive maintenance based on actual performance trends, not guesswork. Energy usage can be analyzed and optimized across entire campuses. Legacy equipment gains new life, integrated securely into modern control architectures without costly rip-and-replace projects.

From industrial plants to smart campuses, this solution turns fragmented HVAC systems into a coordinated, energy-smart asset - proving that sometimes, the biggest energy savings come not from new hardware, but from smarter connections.

SUCCESS STORY: Built to last, Engineered for Now

Sasol Mining - South Africa's third-largest coal producer - relies on rock-solid industrial communications across its six underground mines in Mpumalanga and the Free State. With over 30 million tons of annual output feeding its Secunda and Sasolburg synthetic fuels complexes, network failure is not an option.

Facing aging copper-based systems with limited bandwidth, Sasol needed a cost-effective, non-disruptive upgrade that leveraged its existing telecom infrastructure. Partnering with Throughput Technologies, they deployed Westermo's Wolverine Managed Ethernet Extenders (DDW-142/242). These units deliver up to 15.3 Mbit/s over legacy copper, enabling not only reliable PLC communication between central offices and remote substations - but also high-quality video surveillance on the same network.

The solution's ease of deployment was key. Thanks to Westermo's unified WeOS platform, configuration was seamless, consistent, and future-proof. “Throughput, with Westermo, delivers solutions compatible with products sold over 30 years ago,” Sasol confirmed. “WeOS ensures today's investment integrates smoothly with tomorrow's technology.”

At the Twistdraai Export Plant, ProSoft RLX2-IHNF industrial Wi-Fi radios further enhanced reliability by wirelessly connecting stacker-reclaimers to the SCADA control room - ensuring real-time operational visibility.

The result? A stable, high-performance, and scalable OT network that supports predictive maintenance, remote monitoring, and digital transformation - without costly rewiring or downtime. In an industry where every minute counts, Sasol's modernized infrastructure proves that resilience and innovation go hand in hand.

Industry 5.0: Designing the Next Standard of Industrial Operations

The next phase of industrial evolution is not about faster automation, but about how people and intelligent systems collaborate to create resilient, sustainable operations suited to long-term industrial reality.

From Automation to Collaboration

Industry 4.0 transformed operations through automation, connectivity, and large-scale data use. Industry 5.0 builds on this foundation by reintroducing human judgment as a critical system component. Machines handle speed and scale, while people provide context, oversight, and accountability. The outcome is not reduced automation, but more balanced decision-making.

Human-Centric, by Design

Industry 5.0 prioritizes systems that support operators and engineers rather than replace them. Safety, transparency, and usability become core design principles, enabling confident human intervention when systems behave unexpectedly or conditions change.

Sustainability as an Operating Requirement

Efficiency alone is no longer sufficient. Industry 5.0 embeds sustainability into daily operations through energy-aware systems, extended asset lifecycles, and responsible use of resources. Sustainability, becomes an operational discipline, not a reporting exercise.

Infrastructure for the New Standard

As Industry 5.0 becomes standard practice, resilient industrial networks, secure OT environments, and flexible architectures form the foundation for reliable collaboration between people and intelligent systems.

With Industry 5.0 it is about building industrial systems that endure.

SA’s Infrastructure Momentum: Major Projects Shaping 2026

South Africa stands on the cusp of transformative growth in rail, smart cities, manufacturing, and renewables - creating outstanding opportunities for robust industrial data communications.

Rail Revitalisation takes centre stage with the Open Access policy enabling private operators on Transnet tracks. Eleven approved Train Operating Companies are set to boost freight volumes significantly. Private investments, like Traxtion's R3.4 billion in locomotives and wagons, promise jobs and local content growth. Transnet's R127 billion modernisation plan targets network upgrades, port efficiency, and security enhancements. Meanwhile, PRASA advances new locally-built trains, fibre-optic signalling, smart ticketing, and depot modernisation, with Gautrain extensions linking new stations and Lanseria Airport.

Smart Cities gain momentum under the national Smart Cities Framework. Cape Town leads with smart metering, CCTV, and fibre networks. Johannesburg and Tshwane leverage data analytics for urban management. Emerging developments like Lanseria Smart City, Mooikloof Mega City, and Leratong City prioritise green, digitally connected living - integrating IoT, AI, and sustainable design for inclusive, efficient communities.

Smart Manufacturing accelerates Industry 4.0 adoption, blending AI, IoT, robotics, and big data. Initiatives from the DTIC and CSIR support SMMEs with Manufacturing Execution Systems, driving productivity, resource efficiency, and global competitiveness despite legacy and skills challenges.

Renewable Energy surges forward through the South African Renewable Energy Masterplan (SAREM). Solar and wind projects dominate, backed by private funding and the Just Energy Transition partnership, reducing coal reliance while expanding transmission capacity.

These initiatives signal a vibrant, technology-driven future - ripe for resilient networking solutions that ensure connectivity, security, and sustainability.

In the words of Horace: Carpe Diem - seize the day.